Complex offer

Our comprehensive offer includes the design, production and maintenance of tools for extrusion of plastics. At the same time, we provide services in the field of electrical discharge machining (WEDM, EDM), machining (turning, milling) and finishing abrasive treatment (surface grinding).

Technical consultancy

We also offer a wide range of technical consultancy, including the design of profile systems, tooling parts, machines, devices based on analyses and simulations using Ansys and CAD software.

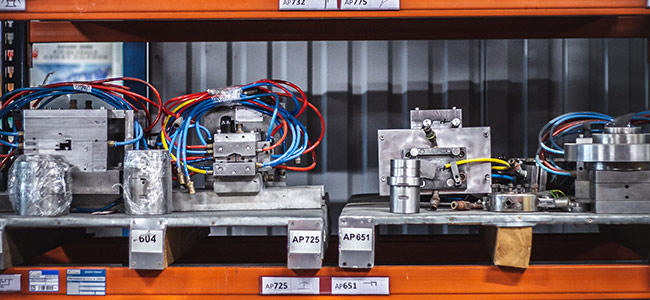

Extrusion tools

We design and manufacture highly efficient profile extrusion tools of various construction:

- multi-chambered profiles,

- chambered profiles with open offshoots,

- full profiles,

- complex and multi-component profiles,

- core profiles,

Based on many years of experience, we adjust the type of extrusion head and the accompanying calibrating and cooling system (calibrators, cooling bath) to the requirements of the finished product.

As a long-term manufacturer of window systems, can we design and manufacture tools for the production of PVC-U chambered profiles weighing up to 3.5 kg.

We make heads for co-extruded and post-co-extruded profiles for joining compatible thermoplastic materials of different hardness.

Maintenance of tools for extrusion of plastics

Service of tools includes:

- periodic inspections,

- maintenance,

- cleaning,

- polishing,

- replacement of worn out or damaged elements

We build tools for the extrusion of plastics such as:

- Hard and soft polyvinyl chloride – PVC-U, PVC-P

- Acrylonitrile butadiene styrene copolymer – ABS

- Polystyrene – PS, HIPS

- Polypropylene – PP-H, PP-C, PPTV

- Polyethylene – LDPE, HDPE

- Polymethyl methacrylate – PMMA

- Polycarbonate – PC

- Polyamide – PA, PAGF

- Acrylonitrile styrene acrylic copolymer – ASA