Design – computer tool construction – CAD processing

The use of constantly updated Ansys Polyflow software by our R&D designers ensures that each extrusion tool is optimally adapted to the requirements of the type of extruded profile and the client’s production standards.

We use advanced CAD software to support the work at every stage of designing and manufacturing individual tooling components.

Designing in Autodesk Inventor helps detect design errors by checking virtual prototypes in a 3D environment before manufacturing. We also use prototyping with the use of 3D printing technology as the next stage of verification at the project implementation stage.

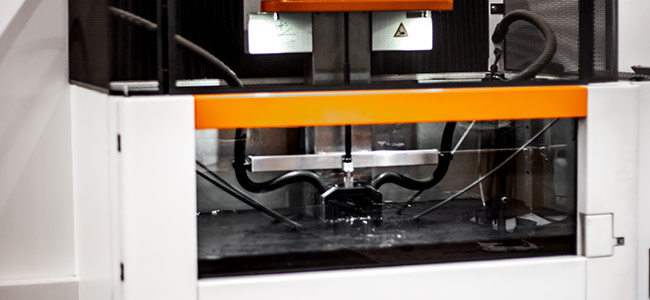

Machines and equipment for the construction of tools

Our Tool Manufacturing Department is equipped with a modern machine park (wire and sinker EDM machines, lathes, milling machines, drills, grinders, saws, etc.), the use of which is monitored by the ERP tool module.

All tools are entirely manufactured using chrome (15% Cr) stainless steel with good ductility, corrosion resistance, abrasion resistance and improved machining and polishing qualities. This allows our company to guarantee that the dimensional and aesthetic characteristics of the extruded profile do not change over time due to premature wear.

Final works – manual precision fitting and assembly of tools

Assembly works and the assembly of individual elements are performed by our technicians who, thanks to their competence and the use of professional tools and supervised measuring devices, guarantee reliability and high quality of assembly.

Finishing of tools/ Testing and first trial

The availability of a variety of single and twin-screw extruders with different outputs and the construction of plasticizing systems allows testing tools for extrusion of many types of materials, from profiles weighing a few grams per meter, to profiles with very large cross-sections and weights. It also allows to recreate the extrusion conditions that will be used by customers at the production stage.

It would not be possible if it were not for the presence in our team of experienced expert technicians dealing with tests at Thermoplast Technology P.S.A. and, upon request, at the client’s.